50% less soil scraping

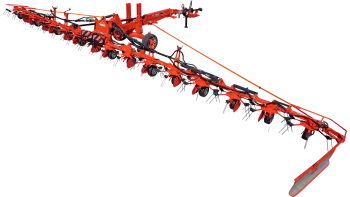

Like their smaller counterparts, the GF 15003 T and GF 17003 T tedders follow the unevenness of the land. For example, the GF 17003 T behaves like an eight-rotor tedder or four four-rotor tedders

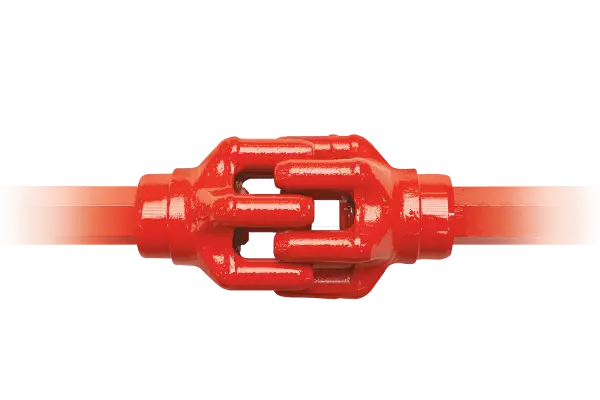

This excellent ground following is primarily due to the exclusive GSC (Ground Save Control) system. An oblong hole in the hitch allows the beam where the rotors are attached to oscillate independently of the chassis. The rotors are guided by the unevenness of the terrain and not by the carrying chassis.

Some exceptional features:

This excellent ground following is primarily due to the exclusive GSC (Ground Save Control) system. An oblong hole in the hitch allows the beam where the rotors are attached to oscillate independently of the chassis. The rotors are guided by the unevenness of the terrain and not by the carrying chassis.

Some exceptional features:

- The exclusive GSC (Ground Save Control) system allows the rotor train to oscillate independently of the carrying chassis.

- When working, the weight of the chassis rests on the large transport wheels.

- The small diameter rotors adapt individually to the ground profile and the carrying chassis, ensuring efficient turning over and fast drying of the forage.

- The wheels, which are located as close as possible to the tines, limit impurities being introduced into the windrows and ensures a long service life for the tines.