Your benefits

Seedbed of superior quality

The tine holders of the KUHN power harrows are positioned in a specific way to create a gradual soil mixing. This precise and exclusive design prevents the harrow from being affected by negative vibrations while reducing power consumption.

Controlling the depth

The height adjustment of the roller is easily done by means of limiting pins. Free to move downward, the roller retains all its grip, even if the machine was to lift slightly during work. The rounded shape of the pin and the stop ensures a large contact area.

Perfect finish

The specific design of the side deflectors guide and channel the soil to ensure good finish between passes. Fixed on the HRB roller arms, the deflectors follow the working height of the roller. On the HR 1004 series, they are mounted on reinforced arms. The efficiency and quality of work are maintained even in stony conditions.

Pease of mind with the simple, robust

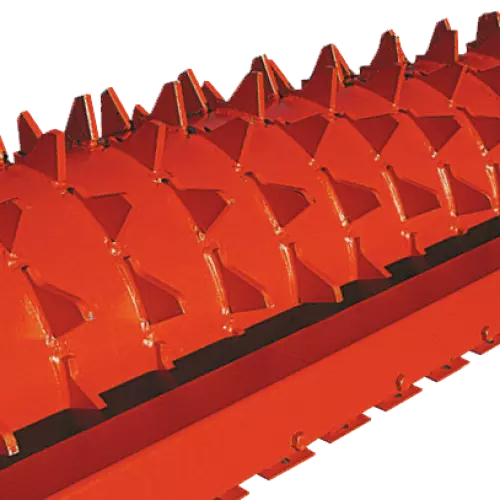

A rotor sometimes copied never matched

The powerful rotor drive is fully protected by a rigid gearbox and trough. The casing, bearings and tine holders form a compact and very sturdy assembly, limiting the torsion stress on the casing. The rotor has a high-rigidity, maintenance-free trough. The curved profile of the forged steel sprockets ensure that the gears are in line with the upper bearings. The maintenance free bearings create a permanent hold, eliminating any risk of play. The sealing is reinforced by a cassette seal on the HR and a lip seal on the HRB. The conical centering of the blade holder (KUHN patent) eliminates any risk of play in the splines. The blade holder is oval-shaped, avoiding blockages of stones and encouraging their evacuation.

Reliable driveline and gearbox

The rotors are driven by large diameter gears. Therefore, the power transmission to the tines is through a large number of intermeshing teeth to transfer the torque loading.

Most KUHN power harrows are equipped with duplex gearboxes. Thanks to their interchangeable sprockets, you can choose the speed most suited to your needs. The entire driveline is protected by a cam type cut-out clutch.

Most KUHN power harrows are equipped with duplex gearboxes. Thanks to their interchangeable sprockets, you can choose the speed most suited to your needs. The entire driveline is protected by a cam type cut-out clutch.

A robust central frame, linkage and headstock

On models with 4 and 5 m working width, the central frame is made with large section profiles ensuring good rigidity and high bending and torsion resistance. For even more simplicity and comfort, some models have hydraulic locking in transport position.

The central frame of the HR 6004 DRC power harrow is composed of a double front and rear frame made of large section rectangular profiles.

The high-capacity 3-point linkage, made from heat treated steel to reduce wear, pivot to allow the machine to follow the ground contours. The headstock is designed and made from steel plate formed and welded ensuring a high resistance.

The central frame of the HR 6004 DRC power harrow is composed of a double front and rear frame made of large section rectangular profiles.

The high-capacity 3-point linkage, made from heat treated steel to reduce wear, pivot to allow the machine to follow the ground contours. The headstock is designed and made from steel plate formed and welded ensuring a high resistance.

A power-harrow suited to your conditions

A large choice for increased versatility of the HR 104-1004 range

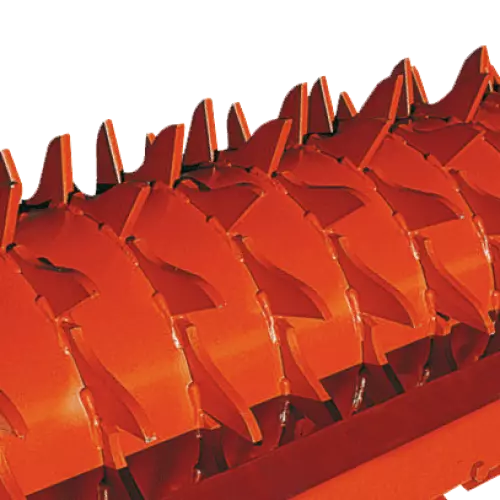

The FAST-FIT tines are fitted as standard on the KUHN HR 104 & 1004 power harrow range. They have a bevelled and twisted shape that creates a fine tilth on the surface, perfect for germination even in difficult conditions (stony, hard and clay soils). They are also adapted to high groundspeeds.

The OPTIMIX tines feature an exclusive design which ensure a quality seedbed in stubble cultivations, subsoiled ground or following pasture regeneration. The aggressive design of the OPTIMIX tines ensure greater soil movement and a greater soil to residue mix.

To increase the service life, KUHN offers hard coated DURAKUHN tines.

For deeper cultivations, 36 cm extra long tines are also available for specialist crops.

The OPTIMIX tines feature an exclusive design which ensure a quality seedbed in stubble cultivations, subsoiled ground or following pasture regeneration. The aggressive design of the OPTIMIX tines ensure greater soil movement and a greater soil to residue mix.

To increase the service life, KUHN offers hard coated DURAKUHN tines.

For deeper cultivations, 36 cm extra long tines are also available for specialist crops.

A wide range of rotor speeds available

A wide range of gear sets can ordered as an option to match your requirements. Also, the gears inside the duplex gearbox can be reversed to offer a wide range of speeds in order to adapt the crumbling intensity. The PTO input set towards the rear of the machine reduces the u-joint angle and makes it easier to lift the power harrow during headland turns.

Easily and quickly adjust the settings

KUHN folding power harrows can be used in rigid or floating position thanks to their articulated central frame. In just a few minutes, you can adapt the tool to the conditions and terrain by simply pivoting an oblong-holed plate.

All HRB 103 DR series and HR 1004 DR series models are equipped with standard height-adjustable side deflectors for improved adaptation to different working conditions. Articulated, they are fitted with spring safety incase of contact with an obstacle.

All HRB 103 DR series and HR 1004 DR series models are equipped with standard height-adjustable side deflectors for improved adaptation to different working conditions. Articulated, they are fitted with spring safety incase of contact with an obstacle.

Equipment

A wide choice of rollers for all conditions. Better equipped with track eradicators, hydraulic coupling, front levelling share and rear levelling bar.

Specifications

Technical characteristics

| Working width approx. (m) |

|---|

| Overall width (m) |

| Maximum tractor power (kW/hp) at 1000 min-1 |

| Minimum power requirement (kW/hp) at 1000 min-1 |

| Gearbox |

| Rear PTO output |

| Rear PTO (same rotation as tractor) |

| PTO safety |

| PTO speed (min-1) |

| Rotor speed 1000 min-1 |

| Type of blades |

| Number of rotors |

| Side deflectors |

| Hitch |

| Approx. weight. (kg) with Crumbler roller with removable tubes Ø 390 mm |

| Approx. weight (kg) with Maxicrumbler roller Ø 520 mm |

| Approx. weight (kg) with Packer PK2 / Packer PK2 HD roller Ø 515 mm |

| Approx. weight (kg) with Maxipacker roller Ø 535 mm |

| Approx. weight (kg) with Steelliner roller 12.5 cm row spacing Ø 550 mm |

| Approx. weight (kg) with Steelliner roller 15 cm row spacing Ø 550 mm |

| HR 304 D | HR 404 D | HR 3004 D | HR 3504 D | HR 4004 D |

|---|---|---|---|---|

| 3.00 | 4.00 | 3.00 | 3.44 | 4.00 |

| 3.12 | 4.11 | 3.08 | 3.50 | 4.10 |

| 139 / 190 | 139 / 190 | 184 / 250 | 184 / 250 | 184 / 250 |

| 59 / 80 | 73 / 100 | 59 / 80 | 66 / 90 | 73 / 100 |

| DUPLEX with gear selection by interchangeable gears | DUPLEX with gear selection by interchangeable gears | DUPLEX with gear selection by interchangeable gears | DUPLEX with gear selection by interchangeable gears | DUPLEX with gear selection by interchangeable gears |

| As standard | As standard | |||

| As standard | As standard | As standard | As standard | As standard |

| Cam type cut-out clutch | Cam type cut-out clutch | Cam type cut-out clutch | Cam type cut-out clutch | Cam type cut-out clutch |

| 540 / 750 / 1000 (factory set) | 540 / 750 / 1000 (factory set) | 1000 | 1000 | 1000 |

| 270 (factory set) / 360 | 270 (factory set) / 360 | 230 / 313 (see table of rotational speeds page) | 230 / 313 (see table of rotational speeds page) | 230 / 313 (see table of rotational speeds page) |

| FAST-FIT with boron steel blades | FAST-FIT with boron steel blades | FAST-FIT with boron steel blades | FAST-FIT with boron steel blades | FAST-FIT with boron steel blades |

| 10 | 14 | 10 | 12 | 14 |

| As standard - With spring safety | As standard - With spring safety | |||

| Cat. 2 and 3N (pivoting lower links cat.2 as standard - cat.3N to order from KUHN Parts) | Cat. 2 and 3 with pivoting lower links | Cat. 2 and 3N (pivoting lower links cat.2 as standard - cat.3N to order from KUHN Parts) | Cat. 2 and 3 with pivoting lower links | Cat. 2 and 3 with pivoting lower links |

| 1090 | - | 1185 | - | - |

| 1100 | 1470 | 1195 | 1400 | 1580 |

| 1295 | 1740 | 1390 | 1635 | 1850 |

| 1325 | 1790 | 1420 | 1685 | 1900 |

| 1550 | 1840 | 2095 | ||

| 1450 | 1950 |

Media

User Stories:HR 104-1004 / HRB 102-103

![dakin_farms_test_1]()

John and James Dakin Farmer

Read this reviewCheshire-based farmers, John and James Dakin, have increased drilling productivity across their 800 acres of arable land by upgrading to a wider combination drill which is equipped with a front seed hopper for improved weight distribution and reduced soil compaction.