Your benefits

Easy adjustments mean precise seeding

The roller frame of both tillage tools is equipped with patented linkage parts that make it easier to hitch and unhitch the VENTA seed drill. Uncoupling is quickly carried out, if you want to work solo with the power harrow or change tool.

Calibrate and vary seed rate

Less getting on and off the tractor with the calibration button at the rear of the machine. For night work you can light the LED on the metering unit and the hopper, for working precision. The electric metering unit allows you to adapt the application rate precisely to field conditions. Effective application rate modulation (VRA) is carried out by application maps loaded on the ISOBUS terminal.

Set seeding depth and adjust the covering harrow

A ratchet on either side of the drill enables you to adapt seed depth accurately to working conditions. You can also adapt the pressure of the power harrow to your working conditions and seed type with its centralised settings.

Higher precision in all conditions

Suffolk coulters, double discs or SEEDFLEX seeding units

The VENTA 1010 series seed drill is fitted with coulter seeding units requiring little maintenance. Their adjustable lower stop and 35 kg pressure per unit ensure constant optimal depth on all rows, in particular on sticky or ploughed soil. Take advantage of the 33 cm row spacing and the three rows of coulters to sow in all types of clay soils. The parallelogram allows adjusting the coulter bar height by positioning the lower stop at the required depth.

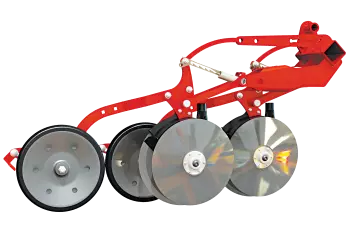

The VENTA 1020 series integrated pneumatic seed drill is equipped with a double-disc coulter bar for efficient sowing in large amounts of plant residues. Reliable and versatile, this seed drill is designed to sow in difficult conditions. The disc ground pressure of up to 35 kg ensures a regular seeding depth even in heterogeneous soils. Discs are also fitted with internal scrapers. The covering harrow fitted on a parallelogramme ensures a perfect seedbed finish also in plant residues or heavy and light soils.

VENTA 1030 series are fitted with SEEDFLEX coulter bars with offset double discs allowing perfect furrow opening. The discs are fitted on a parallelogramme equipped with a press wheel for precise control of the seeding depth of each seeding unit. With a 35 cm clearance between the front and rear rows, SEEDFLEX seeding units are adapted to different use even in difficult conditions and without maintenance. The hydraulic working depth adjustment is available as optional equipment.

The VENTA 1020 series integrated pneumatic seed drill is equipped with a double-disc coulter bar for efficient sowing in large amounts of plant residues. Reliable and versatile, this seed drill is designed to sow in difficult conditions. The disc ground pressure of up to 35 kg ensures a regular seeding depth even in heterogeneous soils. Discs are also fitted with internal scrapers. The covering harrow fitted on a parallelogramme ensures a perfect seedbed finish also in plant residues or heavy and light soils.

VENTA 1030 series are fitted with SEEDFLEX coulter bars with offset double discs allowing perfect furrow opening. The discs are fitted on a parallelogramme equipped with a press wheel for precise control of the seeding depth of each seeding unit. With a 35 cm clearance between the front and rear rows, SEEDFLEX seeding units are adapted to different use even in difficult conditions and without maintenance. The hydraulic working depth adjustment is available as optional equipment.

VENTA electric drive metering system

The VENTA metering system is renowned for its simple design and precise metering. The centralised metering system has large volumetric fluting for large seeds (wheat, barley, pea, bean…) as well as small fluting for small seeds (rape, alfalfa...). It manages application rates from 1 to 430 kg/ha. The metering unit is electrically driven so it is possible to modulate application rate during work, either manually or by GPS without getting out of the cab. This reliable, robust drive system requires no maintenance. The VENTA seed drill is equipped with an agitator that is easy to disengage if necessary. Its role is to ensure regular seed flow at the entrance to the distribution head. The VENTA seed drill is also equipped with radar that gives a precise speed signal.

New patented frame and seed drill fitted to the roller frame

KUHN has developed a new patented M-shaped frame. Direct visibility of seeding units is improved so that you can control your operation better from the tractor cab. The tillage tool has no effect on seeding depth. Working depth adjustment of the coulter bar and working depth of the power harrow are totally independent. Adjusting one does not affect the position of the other.

High capacity, great autonomy

Practical, safe filling

A wide opening makes your hopper easy to fill using a big bag. Seeds are protected from dust and rain by a metal cover with seal. There is a level sensor inside the hopper which indicates seed level during filling. Hopper-filling access is safe and easy, at a comfortable height with step and large platform. A LED light on the metering unit and hopper mean you can work just as precisely at night as in broad daylight.

Equipment

Electronic equipment for ISOBUS and NON ISOBUS seed drills, and comprehensive options to give you extra comfort and precision in managing tramlining.

Media

User Stories:VENTA 1010 - 1020 - 1030

![HOPWOOD-TESTIMONIAL-DRILLING-CULTIVATION-PLOUGH-AGRICULTURE]()

Julian and Scoot Hopwood Farmers

Read this review“We have a Kuhn Venta 4030 pneumatic drill mounted on a Kuhn HR power harrow and this combination has been a real game-changer when it comes to establishment flexibility,” he adds. “With the disc coulter system on the drill, we can operate in a wide range of conditions, from minimum tilled to ploughed ground, with great control of seeding depth from the tractor cab. The quality of the establishment is very visible, with crop covers being complete and very even.