Exclusive EMC technology: right/left adjustment every second

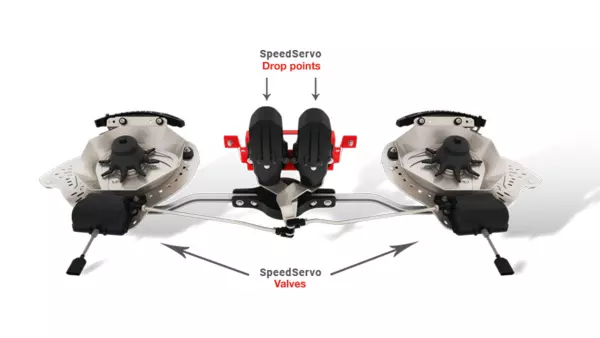

Exclusive EMC technology (Electronic Massflow Control) adjusts the application rate, independently and automatically, on the left and right, every second. The idea is simple: fertiliser flow is measured on each disc so that in the event of clogging or blockage, the flow rate of the outlet concerned is corrected immediately and automatically. This unique KUHN adjustment system ensures every plant on the plot gets the right dose of fertiliser, even on slopes. There's no need to do a calibration test, just enter the application rate and the working width, and start spreading!