Experience faster and more precise farming with SpeedServo technology! This advanced technology allows for unparalleled speed of operation when it comes to dosing hatches and fertilizer drop points. You can now easily and quickly open and close headland shutters in real-time, resulting in increased responsiveness when cutting sections. With SpeedServo technology, dose modulation is instantaneous, making your modulation maps even more effective.

New SpeedServo: switch to ultra-high-speed mode!

SpeedServo technology

The control system is made up of four electric motors that are 2.5 to 5 times faster than traditional cylinders.

SpeedServo provides the metering outlets with new features:

- Instant application rate adjustment by GPS

- Higher precision during variations in groundspeed

- Higher precision during opening/shut-off at headlands

Regulation of spreading in relation to competitors

- It takes more time to change the application rate with a competing control system

- Instantaneous application rate change is possible with SpeedServo!

- GPS technology allows for more precise changes in the application rate

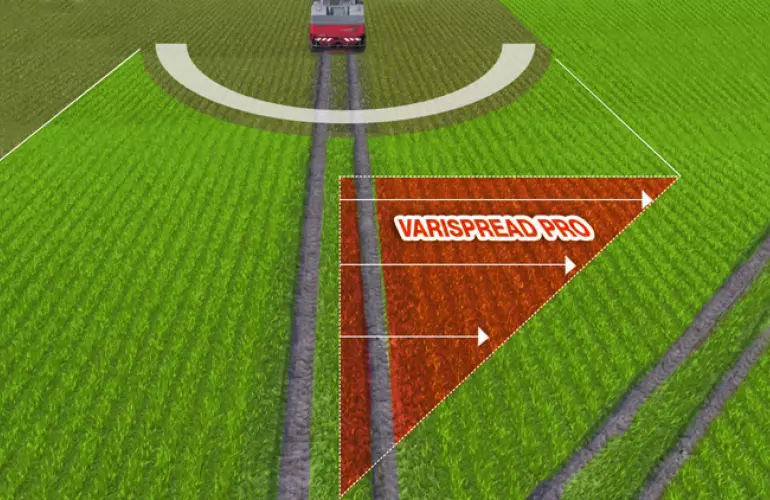

VARISPREAD PRO technology

Continuous section control at very high speed

1 section per metre:

SpeedServo adjusts working width and application rate in field points:

- Continuously and at very high speed

- With more precision as it adapts to the shape of the field

- With improved crosswise distribution

OPTIPOINT innovation

Calculates outlet opening and closing points for each working width and fertiliser type

The spreading process at the headland is managed randomly, with different projection distances depending on the type of fertilizer being used. OPTIPOINT, an automated system, calculates the ideal location for opening and closing the valves based on the fertilizer type and forward speed. This system provides greater precision when controlling the valves through GPS. The spreading process at the headland is managed randomly, with different projection distances depending on the type of fertilizer being used. OPTIPOINT, an automated system, calculates the ideal location for opening and closing the valves based on the fertilizer type and forward speed. This system provides greater precision when controlling the valves through GPS.